Think 3D powered by Teccon

Over the past ten years, Think 3D has become a 3D laser scanning specialist for the industrial market. This includes complex 3D measurements for the petrochemical, food and other industries.

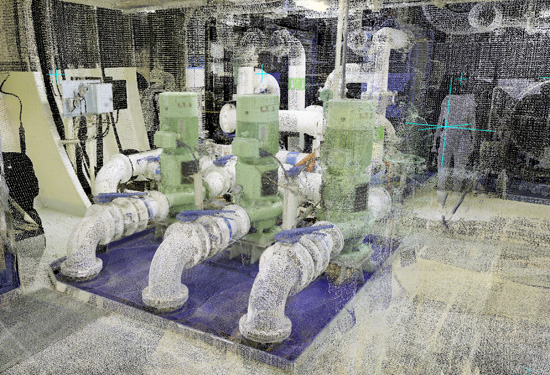

We use 3D laser scanning to establish the existing situation down to the very last detail. Our scans result in a three-dimensional point cloud that forms the basis for 3D displays, 2D plans, 3D models, analyses, basic engineering, clash detection and more.

Think 3D has been part of the expert land surveying firm Teccon since 2020. Our collaboration strengthens the surveying firm’s position in the industrial measurement market, and gives Think 3D clients more options within Teccon’s wide range of services.

3D laser scanning for industry

We perform every scan with particular attention to the scope. This ensures we can take into account the purpose of the scan and its further use within your organisation right from the project preparation stage.

Talk to our experts about your situation!

Our experts are very familiar with technical and industrial environments, and will be happy to help you with your engineering projects and measurement questions.

Please contact us now to discuss your options.

News & Media

3D measurement of ships’ ballast water systems

Does your ship’s ballast water system satisfy the new regulations? From 2024, all ships are required to have an approved Ballast Water Management Treatment System. Think 3D uses 3D laser scanning to map the existing ballast system. This 3D measurement then serves as...

References

“Extra added value, gathering data in a fast and efficient way, low cost”

“Quick availability, maximum satisfaction and above all reliability and transparency in the execution of our last two projects. I hope for more projects together.”

“Our difficulty when replacing a 14.5m stainless steel reactor pipe was making the new pipe exactly the same length as the existing one.But thanks to the 3D scan by Think 3D, we were able to install the new pipe quickly and correctly without any additional costs or loss of time. 3D scans on hot installations with large dimensions with a high level of precision are not easy, but apparently still possible. ”

“Think 3D created a 3D scan of a spray tower which made it possible for us to design the custom heat shield for the tower very precisely.”

“We chose to work together with Think 3D because they’re experts at what they do. They provide clear information in advance and our communications with them are always quick and pleasant. Simply no nonsense, just like us!”